원심 펌프 개요

액체 냉각 시스템을 위한 신뢰할 수 있는 펌프

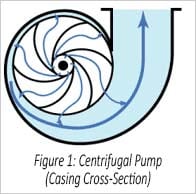

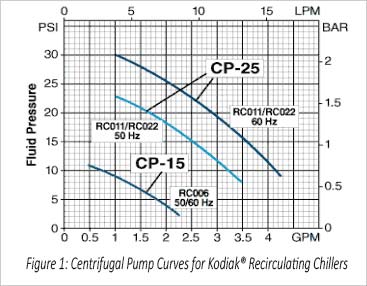

"원심 펌프"라는 용어는 다양한 펌프 기술을 포함합니다. 원심은 "중심 또는 축에서 방향 또는 멀어지기"를 의미하므로 원심 펌프는 회전 임펠러를 사용하여 유체를 바깥쪽으로 이동시킵니다. 유체는 펌프에 들어가서 임펠러의 눈, 또는 중앙으로 그려진 다음 임펠러의 회전 작용에 의해 생성된 원심력을 통해 베인(블레이드)을 통해 바깥쪽으로 강제로 유입됩니다. 유체는 펌프 케이싱(또는 volute)의 외부로 강제로 펌프의 배출을 배출합니다(그림 1 참조). 원심 펌프의 흐름은 시스템 압력 강하에 따라 달라집니다 : 압력이 강할수록 흐름이 낮아집니다.

Boyd의 많은 액체 냉각 시스템은 씰이 없고 자기 구동되는 원심 펌프(mag-drive라고도 함)를 사용합니다. 자기 구동 펌프는 임펠러를 구동하기 위해 두 개의 자석을 사용합니다. 하나의 자석이 모터 샤프트에 부착되며, 일반적으로 "구동 자석"이라고합니다. 다른 자석은 임펠러 ( "구동"또는 "임펠러"자석)에 부착됩니다. 구동 자석이 회전하여 임펠러 자석, 따라서 임펠러가 동일한 속도로 회전합니다. 이 펌프 설계는 모터 샤프트의 회전으로 인한 마찰로 인해 종종 마모되고 누출의 원인이되는 펌프 씰을 제거합니다. 우리의 원심 펌프에서, 구동 자석은 임펠러로 일체로 성형되고 펌프 유체의 오염을 방지하기 위해 열가소성 코팅됩니다. 따라서 "마그 드라이브"는 펌프의 무결성을 보장하고 샤프트 또는 씰 누출의 가능성을 제거합니다.

자기 구동 원심 펌프는 냉각기/냉각 시스템 응용 제품에 선호되는 많은 기능을 갖추고 있습니다. 제대로 작동할 때, 그들은 어떤 중요한 마모 항목이 없기 때문에 원심 펌프의 수명은 크게 물개와 긍정적 인 변위 펌프와 원심 펌프의 그를 초과합니다. 또한 이 설계는 시스템의 필터를 방해할 수 있는 입자를 생성하지 않으므로 펌프의 성능이 시간이 지남에 따라 변경되지 않습니다. 모든 펌프는 유체에 약간의 열을 부여하지만 재순환 냉각기가 엄격한 온도 안정성을 보장하기 위해 펌프에서 추가 된 열을 최소화하는 것이 중요합니다. 매그 드라이브 펌프는 열을 발생시키는 마찰 표면을 최소화하므로 다른 펌프 스타일보다 유체에 훨씬 적은 열을 전달합니다.

다른 설계 이점과 함께 길고 유지 보수가 필요 없는 서비스 수명으로 인해 자기 구동 원심 펌프는 Boyd의 액체 냉각 시스템을 위한 최고의 선택이 되었습니다.

포지티브 변위 펌프의 장점과 작동 원리

PDP 펌프의 작동 방식과 시스템에서 펌프 펌프를 사용하는 시기

압력을 가하여 액체를 이동하도록 설계된 포지티브 변위(PD) 펌프는 로터리 베인, 기어, 나사, 프로그레시브 캐비티, 아르키메데스 나사, 피스톤 및 플런저와 같은 다양한 구성으로 제공됩니다. 역사적으로, 원시적 인 관개 목적으로 수천 년 전에 발명 된 최초의 펌프 중 일부는 긍정적 인 변위 설계였습니다. 수많은 Boyd 냉동 시스템은 로터리 베인 포지티브 변위 구성을 사용합니다. 이러한 유형의 펌프에 대한 다른 응용 분야로는 혼합 후 음료 디스펜서, 에스프레소 커피 머신, 역삼투 물 여과 시스템, 맥주 용 글리콜 냉각 루프 및 용접 토치 쿨러가 있습니다.

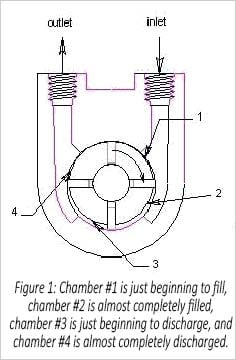

Boyd의 포지티브 변위 펌프의 작동 부품은 황동 또는 스테인레스 스틸 및 탄소 흑연 재료로 만들어지며 모두 신뢰할 수있는 작동에 필요한 고정밀도로 가공됩니다. 이 펌프는 로터의 가공 된 방사형 슬롯을 따라 안팎으로 미끄러지는 흑연 베인으로 형성된 가변 볼륨 챔버를 채우고 배출하여 작동합니다. 로터와 베인 어셈블리는 흑연 재킷에 맞습니다. 로터와 재킷은 오프셋되어 펌프 작동에 필수적인 편심 지오메트리를 생성합니다. (그림 1 참조)

로터가 회전할 때(일반적으로 초당 1725회 회전), 편심 지오메트리는 베인이 홈을 따라 안쪽으로 미끄러지게 하여 입구에서 출구로 이동할 때 각 챔버의 부피를 줄입니다. 펌핑되는 유체는 쉽게 압축되지 않기 때문에 펌프 출구에 도달하면 챔버 밖으로 압착됩니다.

로터가 회전하고 챔버 볼륨이 변경되면 베인이 슬롯에 "부동"됩니다. 원심력과 유압의 조합은 베인을 바깥쪽으로 밀어 하우징의 내부 표면과 접촉하여 효과적인 씰을 제공합니다. 베인과 재킷 사이의 매우 얇은 유체 층은 마찰을 최소화합니다.

이러한 양수 변위 펌프는 자체 프라이밍입니다. 원심 또는 터빈 펌프와 달리 유량은 시스템 압력 강하에 관계없이 일정합니다. 가압을 통해 시스템을 방지하기 위해 펌프는 60 psi에서 유량을 우회하도록 설정된 릴리프 밸브를 통합합니다.

포지티브 변위 펌프는 매우 비용 효율적입니다. 재순환 냉각기를 위해 Boyd는 분당 1.3 ~ 10 갤런의 유속을 갖춘 펌프를 제공합니다. 더 작은 펌프는 황동 또는 스테인레스 스틸 하우징과 함께 사용할 수 있습니다. 황동은 대부분의 응용 분야에 적합합니다. 스테인레스 스틸은 탈 이온화 또는 고순도 물에 권장됩니다. 어떤 펌프가 응용 분야에서 가장 잘 작동하는지에 대해 궁금한 점이 있으면 당사의 응용 엔지니어 중 한 명에게 문의하십시오.

BOYD의 Ambient Liquid Cooling Systems 및 Positive Displacement Pump를 활용하는 재순환 냉각기에 대해 자세히 알아보십시오.

재생 터빈 펌프 소개

재생 터빈 펌프의 작동 방식과 장점

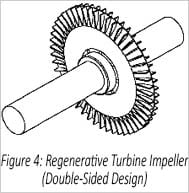

재순환 냉각기와 함께 제공되는 Boyd의 TB-5 터빈 펌프는 재생 터빈 펌프입니다.

재생 터빈 펌프는 종종 원심으로 알려진 펌프의 일반적인 범주로 분류됩니다. 이러한 유형의 펌프는 "정원 종류" 원심 펌프에서 많은 작동 원리를 차용하지만 성능 특성이 상당히 다르기 때문에 유사점은 여기서 끝납니다.

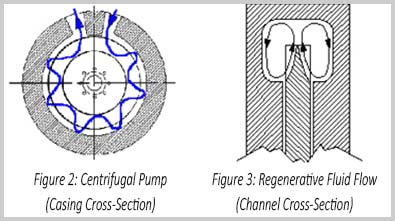

일반적인 원심 펌프에서 유체는 임펠러 (눈)의 중심으로 들어가고 일반적으로 4 ~ 8 개의 회전 베인 중 하나에 의해 "푸시"가 주어지며, 이는 유체에 원심력을 부여합니다 (그림 1 참조). 이 유체 힘은 발루트라고 불리는 임펠러의 주변에서 수집되며, 흐름과 압력을 제공하기 위해 펌프 방전쪽으로 리디렉션됩니다. 재생 터빈에서 유체는 50에서 120 사이의 첫 번째 세트가 임펠러 주변을 향해 방사형 방향으로 원심력을 작은 밀어 주는 주변기에 훨씬 더 가깝게 임펠러로 들어갑니다. 원심 펌프.

Instead of collecting the fluid force and redirecting it immediately out the pump discharge like a centrifugal pump, the water channel, which surrounds the turbine impeller, is shaped to deflect the fluid in a circular path back towards the inside diameter of the impeller vanes (see figures 2 & 3). Here it receives a second push of centrifugal force that increases the fluid velocity which produces the potential pressure capability of the fluid.

An additional benefit of the balanced floating impeller is that very little axial thrust is applied to the motor shaft, which promotes long motor bearing life. These pumps have also undergone substantial performance optimizations to provide the highest pressure capabilities, while still maintaining optimal efficiency. Another feature of these pumps is their excellent low NPSH (net positive suction head) requirements.

Where applications require the units to pump fluids at temperatures very close to their boiling points or pumping low vapor pressure fluids these pumps offer a specially designed pump inlet that gently accelerates the fluid to water channel velocity, dramatically reducing cavitation effects. Even if cavitation occurs, or the fluid already contains entrained vapor, these turbines can handle over 50% vapor by volume. The pumps are also offered with a wide variety of metallurgies and elastomers in easy to repair mechanical seal or sealless configurations.

재순환 냉각기 펌프 선택

재순환 냉각기에 적합한 펌프를 선택하십시오.

요구 사항을 충족하기 위해 재순환 냉각기인 Kodiak을 구성할 때 올바른 유형의 펌프를 선택하는 것이 중요합니다. 시스템의 압력 강하를 기본 의사 결정 규칙으로 사용하는 것이 도움이 될 것입니다.

"내 시스템의 압력 강하는 무엇입니까?" 시스템의 압력 대 유량 곡선을 냉각기의 펌프 곡선에 오버레이합니다. 두 곡선의 교차점은 이 펌프를 사용하는 시스템을 통과하는 예상 유량을 나타냅니다. 예상 유량을 알고 나면 재순환 냉각기 선택 예제에 따라 시스템에 열 부하를 제거하기에 충분한 용량이 있는지 확인할 수 있습니다. 충분한 흐름을 제공하는 곡선을 찾기 위해 여러 곡선을 확인해야 할 수도 있습니다.

시스템의 압력 강하를 모르는 경우 용적식(PD) 펌프를 사용하는 것이 좋습니다. PD 펌프의 유량은 시스템 압력 강하와 무관합니다. 시스템 안전을 위해 이 펌프에는 공장에서 90PSI로 설정된 내부 바이패스가 있습니다. 따라서 시스템 압력 강하가 90PSI보다 크면 이 펌프는 바이패스 모드에서 작동합니다. 직경이 큰 짧은 호스를 사용하여 시스템의 압력 강하를 줄여야 합니다.

펌프 필터

용적식 펌프는 용수 시스템의 입자에 민감합니다. 용적식 펌프를 선택하는 경우 정수 필터를 포함하는 것이 좋습니다. 재순환 냉각기에 정수 필터가 포함된 경우 매주 정수 필터를 점검하는 것이 좋습니다. 새로운 시스템을 사용하면 필터가 시스템 설정 중에 유입된 이물질을 빠르게 축적하여 시스템 성능을 저하시킬 수 있습니다. 새 시스템을 설정한 후 하루 후에 필터 카트리지를 검사하여 필터가 깨끗하고 시스템이 최대 용량으로 작동하는지 확인합니다. 이 초기 필터 검사 후 매주 필터를 점검하십시오. 교체용 필터를 준비해 두는 것이 좋습니다. 펌프 수명을 더 연장하려면 펌프 스트레이너를 주기적으로 검사하고 청소하는 것이 좋습니다. 권장 빈도는 설명서를 확인하십시오.

정수 필터와 탈이온화 카트리지는 원심 펌프와 함께 사용하지 않는 것이 좋습니다. 압력 강하를 너무 많이 증가시켜 유량을 감소시킵니다. 정수 필터 또는 탈이온화 카트리지가 필요한 경우 압력 강하의 영향을 덜 받는 터빈 펌프로 이동하는 것이 좋습니다.

펌프 수명

용적식 펌프에는 위에서 언급했듯이 미립자에 민감한 흑연 핀이 있습니다. 정수 필터를 권장하는 것 외에도 8,000 - 10,000시간 사용마다 펌프를 교체하는 것이 좋습니다. 이렇게 하면 과도한 가동 중지 시간과 관련된 장치 및 비용 손상을 방지할 수 있습니다.

원심 및 터빈 펌프는 물 흐름의 입자에 더 잘 견디므로 PD 펌프보다 수명이 더 깁니다. 이 펌프는 28,000시간마다 교체하는 것이 좋습니다.

펌프 비용

BOYD의 표준 냉각기에는 용적식 펌프가 포함되어 있습니다. 원심 또는 터빈 펌프로 업그레이드하려면 펌프 크기에 따라 추가 요금이 부과됩니다.

펌프 선택에 대한 추가 도움이 필요하면 BOYD 연락하여 엔지니어링 팀과 응용 분야에 대해 논의하십시오.